The #1 Reason For Automation By Popular Vote!

IS IT PROFIT?

NO.

IS IT LOWER INVENTORY?

NO.

IS IT HIGHER YIELD?

NO.

IS IT NO MORE ETHANOL?

NO.

IS IT LESS LABOR?

NO.

KEEP SCROLLING FOR THE ANSWER!

The Answer Can be Found in ICH Q7 Section 5.14

"Closed or contained equipment SHOULD be used whenever appropriate. Where open equipment is used, or equipment is opened, appropriate precautions should be taken to minimize the risk of contamination."

OK. You got it. The #1 Reason Most Popular Reason

IS CONTAINMENT.

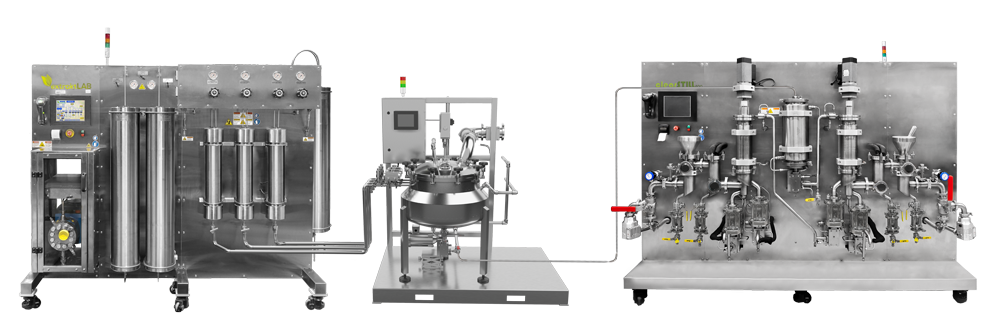

See the Key CONTAINMENT Benefits Below

1. Containment

Containment systems prevent the API from being openly exposed.

Exposure of the API oil will drive many facilities requirements including HVAC (ISO level), floor and wall coverings, gowning levels, particle measurement and validation. Replace your capital intensive Level III rooms with Level II rooms!

Containment systems reduce or eliminate the possibility and risk of external contamination.

2. Validation

A Master Validation Plan gives the framework for validation of processes, facilities, utilities.

Containment systems reduce the number of validation steps including

solvent reuse, winterization, filtration, and decarboxylation.

A single step process is validated as a single step, whereas each separate process is validated

3. Distillate Is Not Always The End Game

Of course, formulations are the end game.

There is no need to stop the containment strategy at distillation. Contact us to explore complete containment through isolation and formulation.

Send the distillate directly to a fully contained isolate system or into another containment vessel to keep the benefits going.